Understanding In-Mold Decorations: Approaches, Patterns, and Finest Practices for Optimum Outcomes

In the world of production, the art of in-mold decors stands as a crucial element of product style and manufacturing. As industries continually look for ingenious means to improve aesthetic appeal and capability, grasping the intricacies of in-mold decorations has actually become a vital capability. From choosing the right products to incorporating sophisticated layout patterns, the journey in the direction of accomplishing ideal lead to this domain name is multifaceted. By delving into the techniques, patterns, and best practices that underpin effective in-mold decor processes, companies can unlock a world of opportunities that not only boost the aesthetic appeal of their products however additionally streamline manufacturing effectiveness and strengthen customer involvement.

Product Selection

Product selection is an essential aspect of mastering in-mold designs, as it directly affects the top quality and durability of the last item. When choosing materials for in-mold decors, it is crucial to think about elements such as compatibility with the molding process, the wanted visual end result, and the ecological conditions the product will encounter.

Additionally, products with high warm resistance are favored for in-mold designs, particularly for items that will be subjected to raised temperature levels throughout their lifecycle. By very carefully selecting the ideal product for in-mold decorations, manufacturers can enhance the overall top quality and longevity of their items, satisfying the expectations of both end-users and clients - In-Mold Decorations.

Layout Advancement

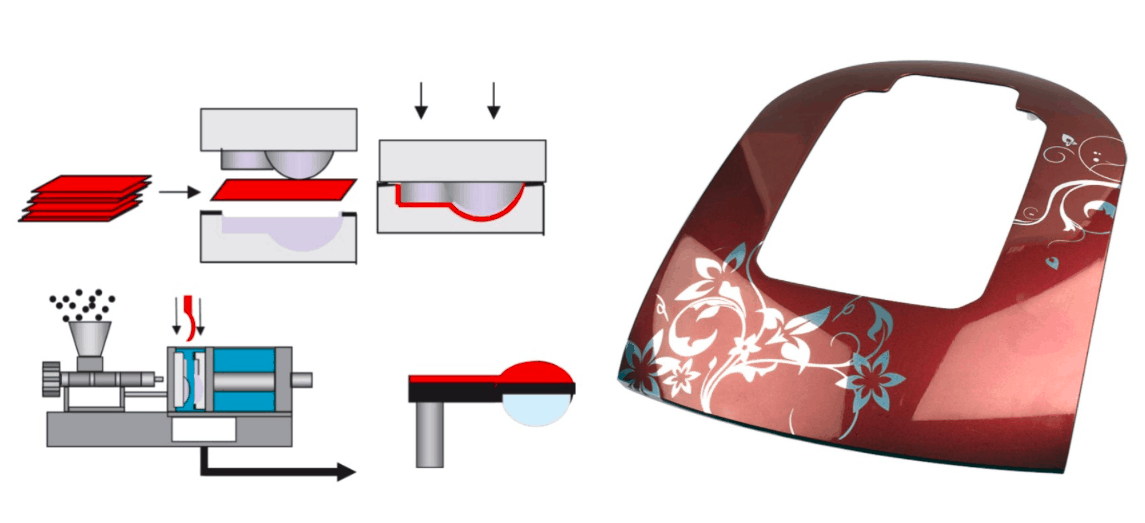

A vital element in advancing the field of in-mold designs is the continual expedition and implementation of style development techniques. Layout technology plays a vital role in enhancing the aesthetic charm, capability, and total top quality of items made using in-mold design procedures. By including ingenious design aspects, makers can differentiate their items on the market, bring in customers, and stay ahead of competitors.

Among the vital aspects of style development in in-mold designs is the assimilation of complex patterns, appearances, and graphics that were formerly challenging to attain with typical decoration methods. Advanced technologies such as 3D printing and electronic style tools allow developers to develop facility and detailed designs that can be effortlessly transferred onto shaped components. Furthermore, making use of vibrant colors, metal finishes, and special results like gloss or matte textures can even more elevate the visual charm of in-mold decorated products.

Furthermore, style advancement prolongs past appearances to include practical improvements such as ergonomic forms, integrated functions, and personalized elements that deal with particular user demands. By accepting style advancement, suppliers can unlock new possibilities for item, imagination, and customization differentiation in the affordable landscape of in-mold decorations.

Manufacturing Effectiveness

Effective production procedures are important for equating the ingenious layouts established in the field of in-mold decorations right into see top notch ended up items that meet market demands and consumer assumptions. In the world of in-mold decorations, production effectiveness incorporates numerous essential elements that add to the overall success of the production process. One crucial element is the optimization of mold and mildew style and tooling to guarantee smooth and precise design transfer onto the last item. By fine-tuning mold setups and buying high-quality tooling materials, makers can improve effectiveness and consistency in manufacturing.

Automation not just increases the manufacturing procedure but likewise enhances precision and repeatability, leading to a more premium and consistent end product. On the whole, an alternative strategy to production performance is critical in making the most of the possibility of in-mold design techniques and achieving optimum results in the affordable market landscape.

High Quality Control Steps

What are the essential techniques for making certain stringent top quality control measures in the world of in-mold decorations? Quality control procedures are extremely important in in-mold decoration processes to ensure the production of high-quality and perfect ended up items. One important technique is the implementation of extensive inspection procedures at every phase of the production process. This involves carrying out thorough visual assessments, dimensional checks, and color uniformity assessments to recognize any problems or inconsistencies early on.

Using sophisticated technologies such as automated inspection systems can additionally boost the quality control process by providing accurate and Find Out More trustworthy data for evaluation. These systems can identify flaws that might be missed out on by manual evaluations, thereby enhancing overall product quality and consistency.

Regular training and advancement programs for workers involved in the in-mold decor procedure can also contribute to maintaining high-quality standards. By educating staff on best techniques, quality expectations, and the significance of focus to information, companies can promote a society of top quality consciousness throughout the organization.

Customer Charm

To boost the bankability of in-mold decoration items, understanding and providing to consumer choices play an important duty in determining their charm and success. Providing personalization alternatives such as customized styles, shade variants, and textural elements can significantly boost the charm of in-mold design items.

Verdict

In-mold designs supply a reliable and versatile method to enhance product aesthetics. Mastering in-mold designs requires an alternative method that considers all aspects of the manufacturing process to guarantee success.

In the world of production, the art of in-mold decors stands as a critical element of item layout and production. Design innovation plays a crucial function in boosting the visual charm, capability, and general high quality of items produced utilizing in-mold decor procedures.One of the key elements of style development in in-mold decors is the assimilation of detailed patterns, structures, and graphics that were previously challenging to attain with traditional design techniques.Effective production processes are essential for equating the ingenious layouts created in the area of in-mold designs right into high-grade ended up items that meet market needs and customer assumptions. Supplying customization choices such as individualized designs, shade variants, and textural aspects can dramatically boost the allure of in-mold decoration products.